Yayyy Blender 🎉

I have very, very little experience in this program compared to Maya and zero experience with sculpting too, so this will be a interesting learning challenge. I’m mostly going to do hard surface sculpting because I’ve seen cool results from other 3D artists in the past and now I have a good opportunity to try it myself.

I’m not quite sure yet how to approach the sculpting, organisation wise, I’ve got a lot of objects that use the same UVs. So I was thinking sculpt one of the objects and then it should transfer to the others that share the same UVs when it is baked. It seemed to work that way when I did a test sculpt of the fantasy sword from week 2’s homework. I didn’t combine my windmill diorama into one mesh yet so it makes it easier to individually select and sculpt parts. I either can import objects one at a time or import the whole model and isolate parts. I’m going to try the latter first.

I think the model looks quite cool in blender’s viewport.

I had to go back and add bevels to the objects I wanted to sculpt as after a bake test, there was some quite bad artefacting from the high poly to low poly bake so…

New “Low Poly” Model

Adding new bevels unfortunately increased the polycount from the previous 115k to around 150k. While most objects stayed the same, some needed some extra segments added using the bevel tool to make them smoother/to a point where I thought it would have the best results when sculpted.

I also had to re-UV everything which was unfortunate. After adding proper chamfered bevels and redoing the UVs, I could finally sculpt details in Blender. To avoid getting too focused and sculpting a whole bunch of details, then still having problems with the bake… I sculpted one part of the model and did a bake + texture test in Substance Painter. This was much better. There’s still some tiny artefacts/small errors near UV seams but its not really noticeable unless you’re super zoomed in.

From there I could continue with the sculpting process, there’s a lot of wooden plank type parts in the diorama so sculpting those was a repetitive process.

I mostly used the scrape, draw and occasionally smooth tools to sculpt details for most of the objects. To make the object sculptable, I used a multiresolution modifier to increase the subdivisions and then applied it once I was ready to export the full sculpt. I’m sure this isn’t exactly proper workflow but it worked well for what I needed it for. I think using the multires modifier also prevented the high poly from becoming too deformed from the original low poly, which was helpful in preventing artefact issues at the baking stage. However I think it might have also restricted the resolution and angle at which I could draw/sculpt lines, I was limited in which, for example, the wood grain could curve/twist as it would result in a pixelated mesh. If I was sculpting from scratch and then retopologising to low poly later, I’m sure this wouldn’t be an issue.

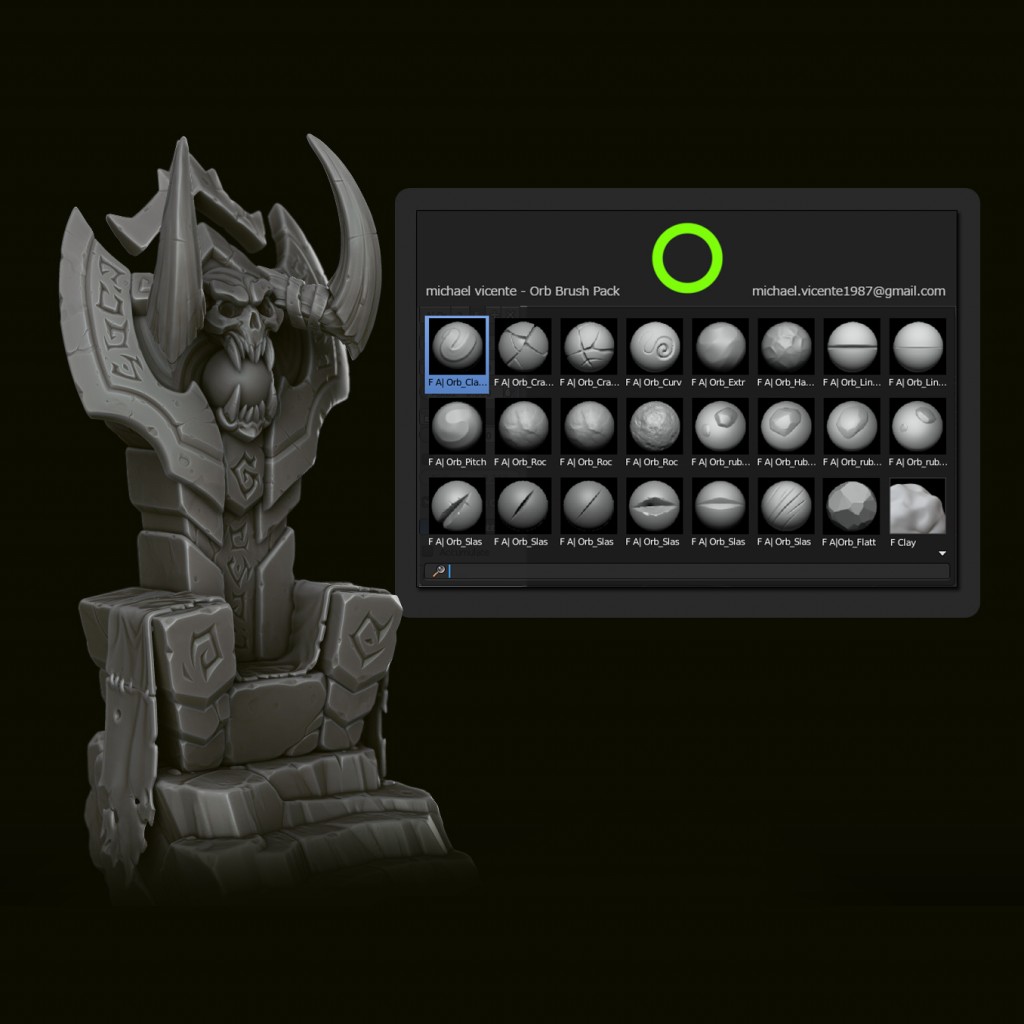

I used a combination of Blender’s default brushes but also this pack:

https://blendswap.com/blend/18735

Thanks to many of the objects sharing the same UVs I only needed to sculpt one of those objects then in Substance Painter the sculpted details would transfer to the other parts in the baking process. I did have problems with some objects not receiving the sculpted details whenever I did bake tests. I was a bit stumped as to why, but I continued sculpting the other parts of the diorama as I had a suspicion why this was happening.

So, when baking, I think Substance didn’t know what UV shell to prioritise baking to as I didn’t move any of the UV shells relating to these wooden pieces on the blades out of the 0,1 space so they were all overlapping each other. The same applies to other areas I thought would bake but didn’t. By keeping the UV shell related to the object I sculpted in Blender in the 0,1 space and moving the others out, I thought this would fix this and thankfully it did.

Comparison between non-baked low poly (Left) and baked normal map details on the same LP model(Right):